Thin biofilm technology converts CO₂ into high-purity biomethane

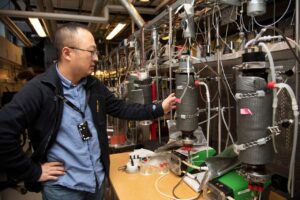

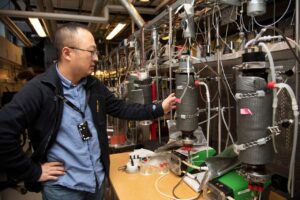

Led by Dr Lu Feng, the team has published five scientific papers documenting how thin layers of microorganisms – known as biofilms – can be engineered to capture and convert gas streams into clean-burning methane.

“Instead of decomposing organic waste, as in traditional biogas production, the biofilm method processes gases directly under oxygen-free conditions,” explained Dr Feng.

“We can steer the process towards efficient CO₂ conversion by introducing specific methane-producing microbes into the reactors.”

The biofilms, grown on small plastic carriers commonly used in water and waste treatment, provide an extensive surface area for microbial activity.

This improves gas–liquid contact, helps retain beneficial microbes, and allows the system to tolerate harmful substances such as ammonia and hydrogen sulphide (H₂S), which typically disrupt methane production.

In trials, biofilm reactors maintained high methane quality even under extreme H₂S levels, whereas systems without biofilm lost up to 30 per cent of their methane output.

Similar resilience was observed under high ammonia conditions, thanks to ammonia-tolerant microbes such as Methanothermobacter, which use hydrogen and CO₂ to generate methane.

In another study, the researchers tested the biofilm method on syngas – a combination of hydrogen and carbon monoxide.

“This could unlock the potential of using waste to produce biomethane, for example plastic waste and woody biomass, which under normal circumstances does not degrade in a bioprocess,” Dr Feng said.

The team found that adding extra hydrogen could increase methane production.

However, too much hydrogen created an imbalance in the process: “This shows that biofilm reactors have great potential, but also that they require careful control to function optimally at industrial scale,” he explained.

“Biofilm-based processes offer a robust and flexible platform for future biogas production. This could become an important contribution to reducing harmful gas emissions while producing renewable energy,” Dr Feng added.